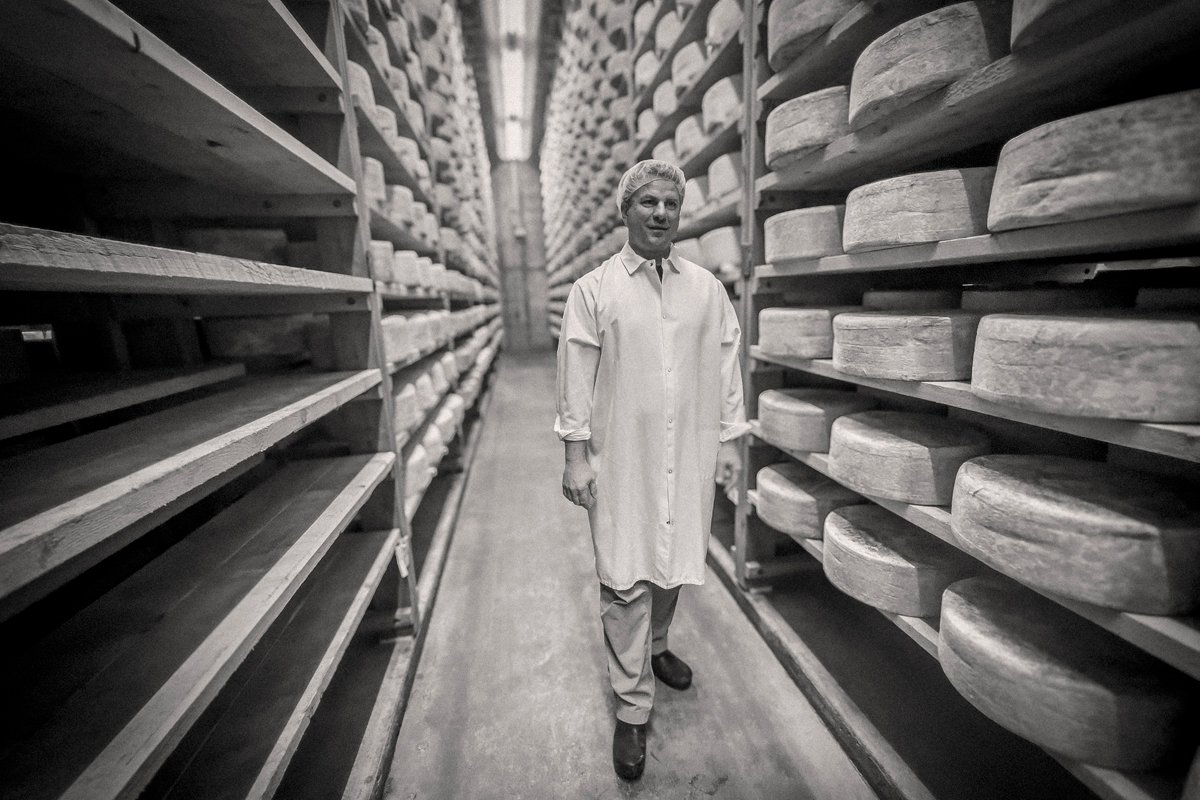

By paying top dollar for milk and sourcing within 15 miles of its creamery, Jasper Hill supports an entire community.

November 11, 2021

Farm to table has become a guiding principle in many corners of the food and wine worlds. But spirits—everything from whiskey to vodka to liqueurs—remain a monument to a broken food system, says Shanna Farrell, author of A Good Drink: In Pursuit of Sustainable Spirits, released in September.

Distillers are wholly disconnected from the farms that grow their ingredients—many even build their products from pre-made base spirits purchased from mass producers such as Midwest Grain Products of Indiana. Even iconic brands full of artificial ingredients like Campari and Aperol are mainstays behind the bar of restaurants that would never serve the equivalent on the plate.

The spirits industry is finally beginning to grapple with the concept of sustainability, says Farrell, a historian and interviewer at the University of California at Berkeley’s Oral History Center who specializes in cocktail and food culture and history. Efforts such as the Environmental Sustainability Working Group established in 2020 by the Distilled Spirits Council are bringing greater awareness to the ecological impact of spirits production and encouraging major players like Bacardi, Moët Hennessy, Rémy Cointreau, and Pernod Ricard to embrace innovations in energy and water use, packaging, and transportation.

Improving the sustainability of industry heavyweights with large, loyal followings, however, moves slowly. By comparison, nimble, small-scale craft distilleries have more flexibility to reduce their carbon footprint, improve the quality and taste of their spirits with family-farmed and heirloom ingredients, and rethink how their products reach consumers. Their efforts are gaining support from small spirits organizations such as the Tin Roof Drink Community and Tales of the Cocktail Foundation, which are working not just to build a greater sense of community among distilleries embracing sustainable practices but to also influence other spirits producers to do the same. The movement gradually gains momentum each year.

In her book, Farrell outlines some of the most innovative distilleries in operation, including South Carolina’s High Wire Distilling, which produces bourbon using locally grown heirloom corn, and Colorado’s Leopold Bros., where everything down to the on-site malting floor and outdoor landscaping was designed by its environmental engineer co-owner.

Civil Eats spoke with her about why distilleries are so disconnected from the farmers that produce their ingredients and how the spirits industry is slowly rolling toward a grain-to-glass spirits revolution.

Distilleries make spirits with agricultural products, but most aren’t using local or sustainably ingredients. Why?

I think there are a few reasons. There’s a disconnect between where we’re getting the ingredients for spirits, because often they are commodity crops [like corn and wheat] that we can’t see grown. There’s not really a direct relationship between distillers and farms. And because of the way spirits are regulated, distillers don’t legally have to list ingredients on their bottles. Food is regulated by the FDA (Food and Drug Administration), and spirits are regulated by the Tax and Trade Bureau (TTB). We’re not looking at a bottle of alcohol and generally thinking the same things as if we were looking at a box of pasta or sauce.

So even though spirits contain agricultural products and are consumed by drinkers, they are not considered food? Why, then, does the FDA regulate drinks like soda or juice but not spirits?

It goes back to before Prohibition to the Whiskey Rebellion [in the 1790s], which happened because there was a lot of whiskey being sold, but the government was upset it wasn’t getting the taxes. Even before Prohibition, alcohol was regulated [and taxed] by the federal government [through the TTB]. If alcohol is high enough proof, it can be sterile, so people aren’t as worried about getting sick the same way they might be about food being produced in a factory. Spirits are subject to the FDA’s Generally Recognized As Safe (GRAS) list, but they are not considered food, so there’s less of an interest in having them regulated by the FDA.

Do you think there’s a moral component to it?

Yes. The TTB regulates tobacco, alcohol, and firearms—things that have negative connotations. I think the moral component that came out of Prohibition is certainly part of it.

You note in your book that high-end bars and restaurants that would never put processed or artificial ingredients on a plate will pour mass-produced alcohol. Does this boil down to a lack of awareness about the ingredients or the absence of alternatives?

It’s a little bit of both. There are definitely some great alternatives on the market, but people don’t know because of the lack of ingredient lists on their bottles. You might not know that there’s red dye 40 in there. You might not know that there’s high fructose corn syrup. It falls to the bar operator to be aware of it and to provide alternatives, but these are just not conversations that are happening in the spirits industry. There’s a lot of money that comes from spirits companies—it’s a huge industry—so often there’s incentive for people to carry a product because they’re getting other perks from a company.

You write that almost all corn-based spirits come from the commodity crop yellow dent field corn. Why are spirits so dependent on industrialized farming?

Yellow dent field corn is really consistent, it’s really resilient, and it has a high enough sugar content to be able to make alcohol. With a commodity crop, you’ll get a steady supply year after year. When you’re using landrace or heirloom varietals of corn for your whiskey, it’s way less consistent, and you are at the mercy of your environment, the weather, [and] whatever’s happening that year.

At High Wire Distilling, [which uses heirloom Jimmy red corn], there have been a couple of years where they don’t really know what kind of crop they’re going to get because it has flooded or there’s been a massive hurricane. It’s hard to bet on something, especially when you’re financially dependent on it.

I was stunned to read that a number of distilleries don’t distill their own corn—they buy a mass-produced base from a larger distributor. Why?

A bunch of distilleries source their base spirit from a giant distillery like Midwest Grain Producers (MGP), and they just age it themselves. There are over 50 whiskey companies that source from there now. That’s a way to get a product to market really fast without having to distill something and then sit on it for two years; they can make money right away. Some new distilleries source from a place like MGP while they are aging their own distilled spirits. Or a lot of people do it if they don’t have the equipment.

Isn’t that just creating the same product with different labels on it?

I think so. That’s one of my big issues with the way that people talk about whiskey, which I think perpetuates the problem. It’s such a common practice where distilleries talk about the type of wood that’s in the barrel to age it or they talk about the weather while it’s being aged. Even the distilleries that distill their own stuff and are using yellow dent field corn. It’s the same corn that everyone else is using, so how do you differentiate? That’s why the dominant narrative has been more about aging and wood instead of the raw ingredients.

What is the difference between the distilleries that use industrialized ingredients and those that are “grain-to-glass” like St. George Spirits in California and Montanya Distillers in Colorado?

They know exactly where their base ingredients are coming from [and how they are grown]. It all comes back to the land. The questions that distillers should ask when sourcing ingredients are different for each category of spirit. What qualifies corn as sustainable isn’t the same as what makes an agave or sugarcane crop sustainable. That being said, a distiller should look for transparency from a farm. Do they practice organic farming? In some cases, it may take years for a farm to convert to organic from conventional. Is it possible to rotate their crops? Are there other crops grown on the farm? Do they irrigate?

If a farm isn’t willing to share that information, it’s hard for a distiller to make an informed choice. But if a distiller and a grower can build a trusting relationship and have open communication, they can work together to create a system that works for both the farm and the distillery. Grain-to-glass also means not putting additives and things like that in, and if you do, disclosing that so people know. Transparency is important.

How does the cost of operating a grain-to-glass and/or sustainable distillery compare to more traditional distilleries of the same size?

Though I didn’t have explicit conversations about cost, it’s reflected in their retail price. It may cost more to source heirloom ingredients that were grown in an eco-conscious way, so the price accounts for this. My feeling is that it’s similar to slow food—high-quality ingredients are more expensive than commodity crops. There are ways to cut costs and be environmentally friendly like using solar power, sourcing local ingredients, or working directly with a farm, but it’s going to be different for each distillery.

What are some other ways that distilleries are decreasing their environmental impact?

Leopold Bros. [in Denver] is a fascinating example. I have no hesitation about saying that it is the most environmentally advanced distillery in the country, if not the world. It’s a small family distillery run by two brothers: Todd, who is the distiller, and Scott, who is an environmental engineer. Scott designed the distillery, and every single component is in service of efficiency. They’re trying to be as efficient with their water use as possible, down to the type of native grass and plants they’ve planted all around the distillery. They use natural disinfectants on their wood fermentation tanks and solar power.

They grow and malt their own barley as well. They use the malt for their whiskey and vodka, and they use that vodka as the base for their gin and liqueurs, so they’re also trying to create less waste that way. They practice wild yeast fermentation. They have the windows open with fans that pull the pollen and wild yeast from the flora outside the distillery over the fermentation tanks. Everything goes back to a sense of place and it being in Colorado.

Distilleries aren’t required to be transparent about their ingredients and environmental practices. Is there a resource to help consumers determine which are grain-to-glass and which use commodity crops and artificial ingredients?

I don’t think so. There are things like carbon footprint generators for cocktails, but there’s really no list. You can find ingredients lists [online] but you have to work for it. It’s hard to make an informed choice. But I feel hopeful. More and more people are thinking about and doing these things. As people experience climate change on a daily basis, these issues are only becoming more important and there’s less resistance.

The first step is to make a mental switch to think about the environmental side of spirits, and then have a conversation. Go to a liquor store and say, “Hey, do you have any products that are made with locally sourced New York state grain?” That’s the place where the consumer can ask questions. I would also expect to pay more per bottle for a spirit that is made in an eco-friendly way than something that is mass produced, like we do with food. Being willing to adjust your habits a little bit goes a long way.

This interview has been edited for length and clarity.

September 4, 2024

By paying top dollar for milk and sourcing within 15 miles of its creamery, Jasper Hill supports an entire community.

September 3, 2024

August 27, 2024

August 26, 2024

Like the story?

Join the conversation.