Recycled plastic can be more toxic than virgin plastic, yet the federal approval process to use it in food packaging is lax and leaving consumers at risk, researchers say.

Recycled plastic can be more toxic than virgin plastic, yet the federal approval process to use it in food packaging is lax and leaving consumers at risk, researchers say.

August 27, 2024

Recycled content in food packaging is increasing as sustainability advocates press manufacturers to cut their use of virgin plastic.

Since 1990, the U.S. Food and Drug Administration (FDA), the agency responsible for ensuring food contact materials are safe, approved at least 347 voluntary manufacturer applications for food contact materials made with recycled plastic, according to a database on its website. Approvals have tripled in recent years, from an average of seven to eight per year through 2019, to 23 per year since then, and they continue to climb. The FDA has already approved 27 proposals through June this year.

Other than Coca-Cola, most manufacturers seeking approval are petrochemical giants such as Eastman Chemicals, Dupont, and Indorama; and lesser-known plastic packaging manufacturers, including many from China, India, and other countries.

“The FDA has been very reluctant to adopt a modern perspective.”

The end buyers of the recycled materials aren’t included in the FDA database, but many popular brands are using recycled content. Cadbury chocolate bars come in a wrapper marketed as 30 percent recycled “soft plastic packaging.” The Coca-Cola Co. in North America reports it sells soft drinks in 100 percent recycled PET (polyethylene terephthalate) bottles, while General Mills says its Annie’s cereal boxes use a liner made from 35 percent recycled plastic film.

Increasing recycled content in packaging may be good news for the planet, but researchers say the FDA has a lax approval process for plastic food packaging that hasn’t kept pace with the science on chemical hazards in plastics. The agency’s approval process for recycled plastics is voluntary and ignores the potential risk of chemical mixtures, researchers told EHN. Companies can seek guidance on their recycling process, but they are not required to. In addition, the FDA relies on manufacturers’ test data when it approves materials, leaving companies essentially in charge of policing themselves. Meanwhile, some studies show that recycled plastic can harbor even more toxic chemicals—such as bisphenol-A (BPA), phthalates, benzene and others—than virgin plastic.

FDA spokesperson Enrico Dinges defended the process, telling EHN the agency “reviews [industry] data against stringent scientific guidelines” and can “use its resources to spot test materials” if it sees an issue.

But researchers say the agency fails to protect the public from the toxic chemical soup found in recycled plastics.

“[The] FDA is most concerned about pathogen contamination coming with the recycled material, rather than chemicals,” Maricel Maffini told EHN. The approval process “is very lax,” she said.

Globally, just 9 percent of plastic is recycled. Most is recycled mechanically, by sorting, washing, grinding, and re-compounding the material into pellets.

Most recycling centers collect a mix of materials, allowing milk jugs, say, to intermingle with detergent bottles or pesticide containers and potentially absorb the hazardous chemicals from those non-food containers. Recycling facilities that are set up to collect one plastic type, such as PET bottles, can better control potential contamination, although chemicals could still be introduced from bottle caps or the adhesives in labels.

Hazardous chemicals can also be introduced when plastics are decontaminated and stabilized during recycling. Plastics degrade with recycling, “so you may need to add more stabilizers to make the material as robust as the virgin material,” Birgit Geueke, senior scientific officer at the nonprofit Food Packaging Forum, told EHN. “Recycling can therefore increase the material complexity and the presence of different additives and degradation products.”

Geueke, who led a review of more than 700 studies on chemicals in plastic food contact items, said that research on recycled plastics is limited. Despite that caveat, “there are a few studies really showing that contamination can be introduced more easily if you use recycled content.”

One study found 524 volatile organic chemicals in recycled PET versus 461 in virgin PET. Chemicals detected in the recycled PET included styrene, benzene, BPA, antimony, formaldehyde, and phthalates—chemicals linked to an array of health issues, including cancer, and the ability to hack hormones and cause development delays in children, obesity, and reproductive problems.

Most studies have focused on recycled PET, which is “not as prone to picking chemicals up,” in comparison to other plastics such as recycled high-density polyethylene (HDPE) and polypropylene, or PP, Geueke said. “HDPE milk bottles really take up chemicals during all stages of their life cycle, much more than PET bottles, and [those chemicals] are harder to remove, because they stick harder to the material,” she said.

Indeed, a study on recycled HDPE pellets obtained from various countries in the Global South identified pesticides, pharmaceuticals, and industrial chemicals in the pellets.

The FDA must authorize all materials that contact food before they reach the market. To be authorized, a material cannot contain intentionally added cancer-causing chemicals nor any other chemicals that leach from the material at a level of more than 0.5 parts per billion.

But as Maffini pointed out, the FDA recommends, but does not require, the type of testing that manufacturers should do to ensure their products are safe, and it doesn’t always require them to submit any safety data, she said.

“If you tell the FDA the substance or substances used to make the plastic are not mutagenic or genotoxicant, and the exposure in the diet would be less than 0.5 parts per billion, FDA does not expect you to send any safety data [to back up these claims].”

In defense, the agency’s Dinges said, “the FDA has robust guidelines for the underlying scientific data that should be provided” by industry. But he also said, “it is the responsibility of the manufacturer to ensure that their material meets all applicable specifications.”

For recycled plastics, companies may also voluntarily submit a requested review of their recycling process. In this case, the FDA asks companies to provide a description of the process, test results showing that the process removes possible incidental contamination, and a description of how the material will be used.

The FDA further advises manufacturers to conduct “surrogate testing,” which involves challenging recycled materials with, or submerging them into, different classes of hazardous chemicals that could theoretically contaminate the plastic, to determine whether the company’s recycling processes can eliminate those toxic chemicals.

Surrogate testing is the “best available practice” for evaluating chemical migration from recycled plastics, Gueke said, although research shows it works better for PET than for other plastics like PP or HDPE. Though the FDA doesn’t require surrogate testing, Tom Neltner, executive director at Unleaded Kids, said, “I don’t think you’re going to find a market in the industry without having gone through FDA review.”

Neltner, who formerly worked with Environmental Defense Fund’s Safer Chemical Initiative, said that in his experience, big food companies are skittish about using mechanically recycled plastic on packaging that touches food.

According to the FDA database of recycled plastic applications, two-thirds of the approvals are for recycled PET, for a broad range of products from drink bottles to clam shell containers for fruits and vegetables to tea bags. Most of the remaining approvals are for recycled PP for products including clam shells, disposable tableware, cutlery, caps, and lids; recycled HDPE for grocery bags, milk and juice bottles, meat trays, and disposable tableware, and recycled polystyrene (PS) for meat and poultry trays and clam shells.

Most requests are for mechanical recycling processes, though a couple dozen were submitted for chemical recycling, which uses an energy-intensive, largely unproven, process to convert plastics back to their original monomer chemicals. [The FDA no longer evaluates chemical recycling proposals for PET because it says the process produces material of suitable purity for food-contact use.]

“The FDA has been very reluctant to adopt a modern perspective,” Tom Zoeller, professor emeritus at the University of Massachusetts Amherst, told EHN, referring to testing for the effects of endocrine disruptors or for the mixtures of chemicals found in plastics.

FDA’s requirement that a chemical not exceed a threshold of 0.5 parts per billion is based on cancer risk, Zoeller said, and while that number is protective for evaluating exposure to a single chemical, “I’m not sure that means a lot, when you consider the 16,000 chemicals that are put in plastic.”

In other words, the FDA’s approach doesn’t account for multiple chemical exposures, even as research shows that chemical mixtures can have significant health impact. A European study, for instance, found that a mixture of nine different chemicals had a greater impact on children’s IQ than what was expected based on individual risk assessments.

“It’s the combination of chemicals that are impacting IQ and basically stealing human potential,” Zoeller said. “We are way behind the curve,” in assessing chemical risks, he added.

Dinges responded that “while it is unlikely that appropriately sourced and controlled feedstock will experience incidental contamination to any appreciable amount, potential incidental contamination is addressed by the FDA’s surrogate testing recommendations.”

Yet the ability to control feedstock is what worries experts. Researchers who found BPA and heavy metals migrating at higher levels from recycled PET compared to virgin PET, stressed that the plastic’s safety depends on transparency and cooperation across the value chain. Moreover, surrogate testing is not required.

Neither does FDA’s approach account for endocrine-disrupting chemicals, which can act at levels in the parts per trillion by disrupting metabolism, Maffini and Zoeller commented. “This concept that there’s a threshold below which there are no effects or no adverse effects is fundamentally incorrect,” said Zoeller.

Dinges countered that the “effects on the endocrine system are just one of many areas of toxicology that the FDA evaluates,” while also repeating industry talking points. “Endocrine activation . . . does not necessarily translate into toxicity,” he wrote. “Consumption of any food (for example, sugar) can activate the endocrine system.”

Such responses have led Zoeller to conclude that FDA has “become a foil for industry,” and that their “precautionary principle is applied to industry, not public health.”

Unless government agencies can do a better job at ensuring manufacturers are keeping chemical hazards out of recycled plastic, experts think it shouldn’t be used for food contact materials.

“I’m not a big fan of recycled plastic and food contact, because it’s really hard to know [if it’s safe], and I think producers have to be more careful than when they produce virgin materials,” Geueke said, adding that she thinks that only recycled PET should be considered because the other types so readily absorb chemical contaminants.

“If you have a very good process and can prove that it gets rid of most of the contaminants . . . but nobody knows whether that really happens or not,” she said.

This article originally appeared in EHN, and is reprinted with permission.

September 4, 2024

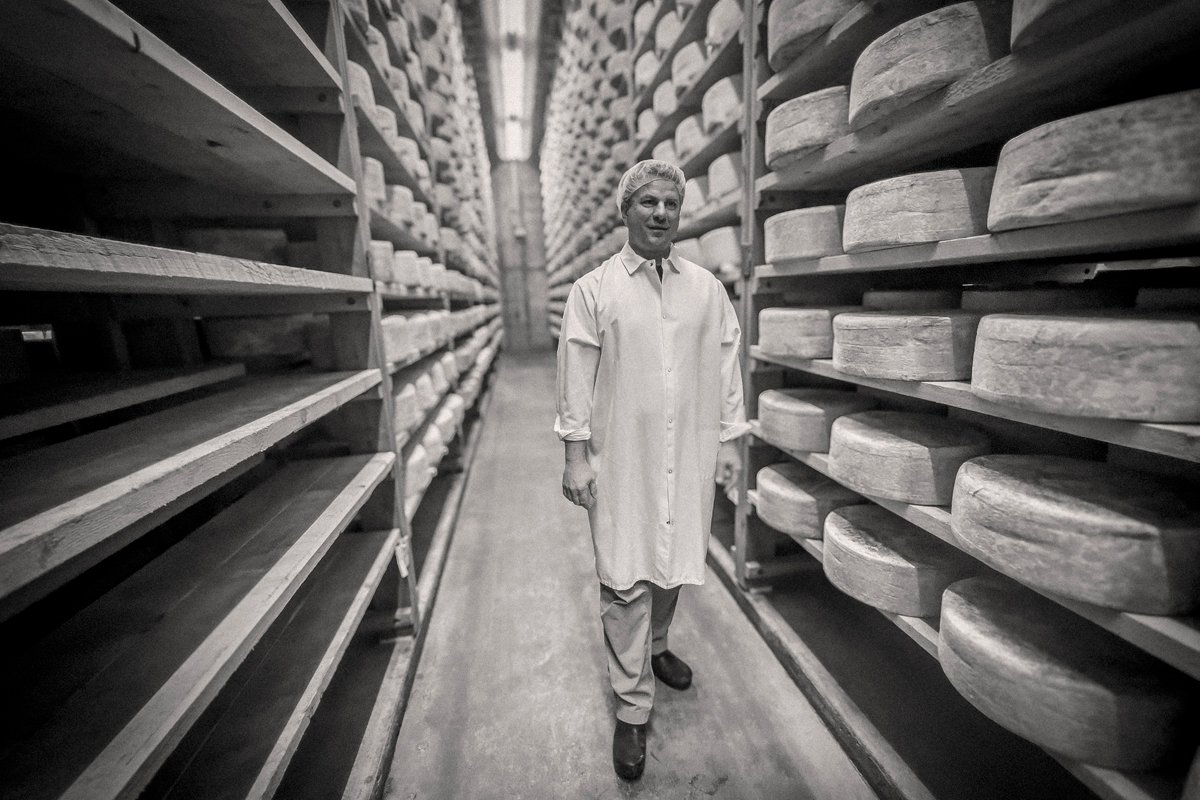

By paying top dollar for milk and sourcing within 15 miles of its creamery, Jasper Hill supports an entire community.

September 3, 2024

August 26, 2024

August 26, 2024

Like the story?

Join the conversation.