In the Midwest, fertile soil is being excavated in pursuit of fossil fuels, while communities suffer.

In the Midwest, fertile soil is being excavated in pursuit of fossil fuels, while communities suffer.

July 19, 2022

An overhead view of Smart Sand’s frac sand mine in La Salle County, Illinois in 2018. (Photo courtesy of Ted Auch)

This article is part of our series of in-depth investigations. Got a tip? Please contact us on our secure email at civileats-at-protonmail.com.

One Monday in June, excavators were tearing into a field in Wedron, Illinois where the nubs of last season’s dried corn stalks were still sticking out of the ground. Behind where the crew worked, strips of earth had been carved out like steps on a wide staircase descending to the bottom of a deep pit. On the far side, fine sand the color of snow was piled in front of soaring, solid walls of sandstone. Picture standing on a ledge looking down into the biggest rock quarry you’ve ever seen. Then, enlarge that image 100 times, whitewash it, and add turquoise blue pools of wastewater. This is silica mining.

Fracking, a process used to extract natural gas and petroleum, depends on silica sand, or “frac sand” to produce the fossil fuels. A single fracking site can use millions of pounds of sand. The sand is blasted into wells to keep fissures in the rock open so that oil and gas can be released.

In the Midwest, farmland is being irreversibly lost in pursuit of silica sand.

Wedron Silica, which is now owned by Ohio-based Covia, has been expanding this particular mine for years and now owns at least 2,500 acres in and around the tiny village. It’s just one of several that Covia owns across LaSalle County, Illinois, 90 miles southwest of Chicago. Here, U.S. Silica, Smart Sand, and other companies are also actively mining.

Together, the companies have purchased hundreds of parcels of land and now own more than 9,000 acres in LaSalle, a Civil Eats investigation has found. The majority of those acres are former or current farmland. Silica mining is also prevalent in other parts of Illinois and regions of Wisconsin and Missouri.

According to the U.S. Department of Agriculture (USDA), LaSalle County’s farmland acreage dropped 5 percent from 2012 to 2017, to 573,000 acres. But many of the acres still identified as farmland are owned by mining companies and leased to farmers. Across the street from the mining activity in Wedron, for example, Covia owns 600 acres, where tiny corn plants were just starting to green up in neat rows. In 2018, the county approved the company’s application to expand into those farm fields, despite the fact that LaSalle County Soil and Water Conservation District discouraged the decision based on a site assessment score that identified the land as “highly productive.” Digging could start at any time.

“You’re taking this short-term demand for sand, and you’re totally sacrificing the long-term agricultural potential.”

Early in the pandemic, declines in fossil fuel prices led to a big drop in demand for frac sand. Now, with oil and gas prices at historic highs with no relief in sight, demand is soaring. In February, one energy consultant told Reuters that current prices for frac sand were “unheard of in the industry’s modern history” and that he expected them to go higher.

“You’re taking this short-term demand for sand, and you’re totally sacrificing the long-term agricultural potential,” says Ted Auch, the Great Lakes program coordinator for the FracTracker Alliance, who has been following the issue for years.

While the more immediate impacts of fracking on communities where the drilling itself takes place have been widely covered, silica sand mining has mostly remained in the shadows. Even on the ground, most residents and tourists visiting LaSalle County’s state parks cannot see the gaping, miles-long craters that extend across the landscape, hidden as they are behind man-made hills called berms, most planted with thick vegetation.

Yet some local residents are watching the mines spring to life with new intensity. “They really are accelerating,” said Joy Konczak, who lives across from a Smart Sand mine in North Utica, where she said that blasting regularly shakes her home. “I was out of town the other day and the neighbor called me and said, ‘Oh my god! My curio cabinet just walked across the floor.”

As the mining picks up, its impacts intersect with other pressing issues. According to American Farmland Trust, farmland is being lost to development at a rate of about 2,000 acres per day, even as the federal government, private industry, and many advocacy groups are betting on that land as a vehicle for carbon sequestration. Meanwhile, young, beginning, and low-income farmers—some of whom are working to farm in ways that require fewer fossil fuels to begin with—are being priced out of land ownership due to development and a growing interest in farmland investment.

County officials have supported the expansion of mines primarily based on the industry’s promises of jobs and economic growth, but in Wedron, for example, there is little left of the village that isn’t mine offices or infrastructure. In the town center, frac sand is loaded directly onto rail cars on the banks of the Fox River. Drivers have to navigate over the sandy tracks to cross the water. At the entrance to the processing plant, the local post office, which the company bought in 2019, sits shuttered, in disrepair.

Civil Eats sent detailed questions to company representatives at Covia, U.S. Silica, and Smart Sand about their expansion and other issues raised in this story. Representatives at Covia and U.S. Silica did not respond. At Smart Sand, finance manager Josh Jayne said, “Thanks for reaching out. We have no comment at this time.”

Past a gray stone fireplace, walls packed with family photos, and a home office tucked between the kitchen and living room, Diane and Phil Gassman sit at their dark wood dining room table with their neighbors Cheryl Illman and Joy Konczak. When they joke about living on an island, Illman spreads out a 2014 zoning map from the village of North Utica, about 20 miles southwest of Wedron.

A strip of green represents a group of about 20 homes, including theirs. The vast sea of red surrounding it represents land that was annexed by the village in 2013 to enable mining. Every parcel is marked “A-1” for agriculture; Covia and Smart Sand own them all.

“We expected them to expand at some point, but we did not feel it would be in our lifetime, and we certainly didn’t expect to be encircled like this. I assumed that would be farmland forever.”

When they moved to the town in the early ‘90s, the group explains, there was a single sand mining company in the center, but it didn’t seem to disrupt the surrounding landscape or their lives. Many of their neighbors were farmers. Looking out the glass door into the Gassmans’ backyard, flowers are blooming near a beehive, and trees block what would be a view of the plant—pictured at the top of this article—which is now owned by Covia.

But over time, the companies snapped up the surrounding farms one by one, often paying as much as $20,000 per acre. “We expected them to expand at some point, but we did not feel it would be in our lifetime, and we certainly didn’t expect to be encircled like this,” Konczak says, gesturing in the other direction, toward the front door, which now looks out onto one of Smart Sand’s berms. “I assumed that would be farmland forever.”

Most of LaSalle County is endlessly flat. What was once prairie is now covered as far as the eye can see with corn and soy fields. But the landscape also has other unique geological features that have long drawn visitors interested in its natural beauty.

At the bottom of the famous St. Louis Canyon in Starved Rock State Park, just across the Illinois River from North Utica, hikers stand on a sandy beach to snap photos of a waterfall framed by walls of St. Peter sandstone. It’s one of 18 canyons in the park formed by a powerful flood from a melting glacier, which carved up the earth and deposited sand along the way. Also key is a geologic fold, called an anticline, that pushed the sandstone up closer to the earth’s surface.

It’s perhaps fitting that at a lookout point at the park’s lodge, visitors can see Covia’s North Utica mining infrastructure just beyond the dense foliage spread out in front of them. After all, the same stone they come to marvel at fueled the frac sand rush.

LaSalle County, with seven frac sand mines, is the country’s unofficial frac sand capital. While Texas is home to the most sand and gravel mining by volume in the nation, Wisconsin and Illinois are close behind, and the sand from this region is considered higher quality for fracking, because of its uniform size and shape. Since the sandstone is close to the surface, mining it is also easier than in other places. Given nearly 80 percent of Illinois’ total land is in farms, the majority of the stone is sitting under cropland.

While the USDA directs some resources toward farmland preservation programs like conservation easements, the federal government does not regulate private land use, farmland or otherwise. LaSalle County and village governments control land use through zoning laws. When a company wants to mine land zoned for agriculture, it must apply for “special use” permits that trigger public hearings. In most cases, officials approve the special use, even when the land and site evaluation shows the land is valuable for farming. (They often add conditions the companies must agree to, addressing issues like blasting frequency, light and noise pollution, and impacts on neighbors’ wells.)

“[The mines] can keep expanding out and down,” said Robert Goodin, a mineral commodity specialist for the U.S. Geological Survey (USGS), citing the vast amount of silica in the region that has yet to be extracted. Smart Sand tells shareholders that based on its current volume, the company could mine the land it owns there for another 161 years.

U.S. Silica runs its operations from a 900-acre pit in the center of Ottawa, a town that sits between North Utica and Wedron and feels like a big city by comparison. The company still operates a processing plant there but its blasting and digging has moved across the Illinois River and is gradually moving west, closer and closer to Starved Rock, where drivers pass the excavation of farm fields minutes before the park entrance sign appears. U.S. Silica secured that continued expansion in 2017 when it bought Mississippi Sand, another frac sand mining company. Years earlier, Mississippi Sand’s application to mine these 300 acres of farmland—which the Conservation District also determined to be “highly productive”—led to significant controversy.

Ted Auch at FracTracker created this interactive map showing all the silica mines around La Salle County, Illinois.

More than 1,000 people signed petitions opposing the mine. During a public hearing that stretched to midnight and had to be extended to a second day, some locals and union representatives voiced support for the project based on the jobs it would provide. Many residents and environmentalists objected, however, based on its proximity to Starved Rock, the health and quality-of-life effects of the mines already in operation, and the loss of farmland. “As the saying goes, they’re not making farmland. It is only to be saved,” Sierra Club volunteer Joyce Blumenshine testified. “Because you can’t eat what is left in that great big pit in the ground when the silica sand is gone.”

The county board approved the permit. U.S. Silica now claims it has just under 100 million tons of “proven and probable” silica reserves in Ottawa, according to a 2022 report to the Securities and Exchange Commission, and its annual production capacity there is 4 million tons, meaning it could operate for another 25 years.

The current high oil and gas prices don’t just increase overall demand for frac sand, they can also drive companies away from cheaper sources toward La Salle’s premium products. “Companies might say it’s worth it to spend more money on those sands, because they will have better flow rates and produce more [fuel],” said Goodin.

“They control the farmer. If the farmer squawks too much, then they take the ground away from him. So, they really have suppressed [dissent] by buying all of this ground.”

While farmland is being destroyed, many land-owning farmers have cashed out by selling their land to the mining companies. Ray Aubry and Bill Stack, founders of a group called Conserve Our Rural Ecosystem (CORE), don’t really blame them. Aubry is a retired educator with 18 grandchildren. His house, just north of Smart Sand’s mine, is surrounded by cropland. On a clear day, if you look west over the alfalfa field outside the front door, you can see the outline of Wedron’s mountain of mined earth on the horizon.

Stack, who lives just to the west, was long what he called a “plain corn-and-bean farmer” while also working an off-farm job. Now, he leases his land to another farmer and raises some cattle.

Together, the pair has tried to raise community awareness of what they see as threats to farmland, food production, and their homeland’s ecosystems. Still, they can rattle off the names of farmers who have sold their acreage for top dollar and bought double or triple the number of acres elsewhere. Those high land prices then shut out farmers with fewer resources, they say. As many of the younger farmers in the region lease land from the mining companies, it makes it harder for Aubry and Stack to organize locals around the impacts the companies are having. “They control the farmer. If the farmer squawks too much, then they take the ground away from him. So, they really have suppressed [dissent] by buying all of this ground,” Aubry said.

In 2016, CORE fought the opening of a new mine in the county with the help of pro bono lawyers from Northwestern University. They succeeded in that one instance, but silica mining continues to expand.

“Farm Land not Frac Sand”—their sign—still stands in a field on the way to Troy Grove, another small village northwest of North Utica. There, another mine stores hulking piles of silica sand right beside a residential neighborhood, and sand lines the street approaching the entrance. On an 85-degree Sunday in June, residents were outside tending their gardens and washing cars. A little boy and girl stood at the top of a ladder on a plastic swimming pool, contemplating the jump into the water below. The mining plant’s rusted infrastructure towered above them, and white particles could be seen blowing through the air, like soft snow.

That “snow” might appear any time of year. In May, Diane Gassman was driving past Smart Sand’s plant on the other side of a farm field about a half mile from her home when she saw what looked like a sandstorm. Smart Sand piles its silica sand right inside the gate there, uncovered. She took out her phone and filmed waves of white blowing hard across the landscape. The wind was intense that day, but on calmer days she says the sand often blows off the property and into the neighborhood. “We’ll come out in the morning and sometimes I will write the word ‘sand’ in it and take a picture, because it’s coating everything,” Gassman said.

While the frac sand itself is not dangerous, mining, processing, and moving it releases fine particulate matter that can include crystalline silica particles. Exposure to particulate matter is linked to respiratory problems such as asthma and decreased lung function, as well as premature death in people with lung or heart conditions. Crystalline silica, specifically, is a known carcinogen, and exposure is associated with increased risk of lung cancer, an irreversible condition called silicosis, and COPD. Because the particles are small enough to travel in the bloodstream to the liver and kidneys, exposure is also linked to kidney and autoimmune diseases. These effects have primarily been observed in workers who are exposed to the dust in mines and at construction sites, and the Occupational Safety and Health Administration (OSHA) has specific regulations in place to protect workers.

“They go to work and wear protective equipment,” Phil Gassman said. “We live in it.”

Of course, the exact degree of daily exposure for the residents of this area is unclear. At the University of Wisconsin-Eau Claire, researcher Crispin Pierce led a team of student researchers that measured levels of particulate matter at sites near frac sand mines. His team found consistently elevated levels, which included crystalline silica, at those sites. Based on the risks associated with the levels they measured, he calculated the associated long-term effects and determined people living near the two facilities lose between 41 and 249 days of life expectancy due to breathing in the polluted air over time.

Dwight Swenson, who lives in Jackson County, Wisconsin, another hotspot for frac sand, said a mine moved in a little over half a mile from his home in 2015. Since then, his previously healthy wife developed lung granulomas, a respiratory condition that can be a precursor to silicosis. Swenson monitors particulate matter on his own, and he said that while the companies fall back on the fact that overall average levels don’t exceed the U.S. Environmental Protection Agency (EPA)’s standard for exposure, levels do go well above what is considered safe on many individual days.

The landscape from the Gassmans’ street: Farmland and silica piles owned by Smart Sand. (Photo by Lisa Held)

According to an EPA spokesperson, “Sand mining facilities are regulated under the Clean Air Act as sources of particulate matter. For this reason, a variety of state and federal regulations and permitting requirements may apply depending on the size of the source, the location of the source, and the nature of the operation.” The spokesperson said the state agency would be in the best position to identify specific requirements for silica mines. The Illinois Department of Natural Resources (IDNR)’s Office of Mines and Minerals did not respond to a specific question regarding whether the agency regulates emissions from sand mines by press time. But a spokesperson said that the agency’s authority was limited to overburden removal, reclamation, and blasting activities. Copies of IDNR silica mine permits obtained via a Freedom of Information Act request do not include provisions related to particulate matter emissions.

“They’re out of compliance almost 30 percent of the time, and we have to breathe all of the time.”

At his home in Wisconsin, “They’re out of compliance almost 30 percent of the time,” Swenson said, “and we have to breathe all of the time.” He and his wife check the levels before deciding whether or not to spend time outside. They also deal with frequent blasting. Usually the windows rattle; once, blasting broke a window.

The word “loss” is paired with farmland to describe a wide range of ongoing processes, but sand mining rarely rates. Most often, land is lost when developers pave it over and build on it. But loss can also happen slowly, as the soil that has supported both vast, natural prairies and America’s agricultural heartland erodes. According to new research, topsoil in the Midwest is eroding at an average rate of about 2 millimeters per year. Since farmers began tilling fields 160 years ago, close to 58 billion metric tons have been lost. In mining industry parlance, that soil filled with life-supporting organic matter and microorganisms is called “overburden,” and getting rid of it to extract the material beneath is the goal.

At the state level, IDNR’s Office of Mines and Minerals has regulatory authority over silica sand mine blasting, overburden removal, and the process called “reclamation.” IDNR defines reclamation as “the reasonable rehabilitation of the affected land to useful purposes, while keeping to a minimum the impact on the surrounding areas” and it requires companies to obtain reclamation permits before they begin mining. IDNR says mining sites could be converted to pastures, forests, wildlife areas, and other uses, and in some places, farmland restoration has been attempted, but it’s difficult to find examples of success.

Wedron Silica has said that farmland restoration is among its aims. In its 2018 expansion plan, the company stated that after reclamation, it would restore the land to “production agriculture, pasture, and gentle slopes to lakes.” But residents wonder whether the companies can and will deliver on their promises. Soil must be replaced, and even when the overburden is put back into the landscape, experts say one thing is clear: the flat, expansive farmland made up of fertile soil formed over thousands of years is not coming back.

“You can imagine it as trying to start a farm on top of a parking lot,” Goodin, at USGS, said. “There are no natural resources left there. It’s just hard rock for miles around. They might have to break up the ground, import soil and organic matter, and bring in plants that can live in the tortured environment.” Flooding the pits with water to create recreational “lakes” is the most popular promise of reclamation, but local residents say to date, the bodies of water left behind have been fenced off and stagnant.

Residents and Ted Auch at FracTracker Alliance said that state and local government officials could do a lot more to regulate the mining companies. They could assess risks more seriously, require more stringent permits around waste and water use and air pollution, and demand companies do serious reclamation on each parcel of land as they go. “The speed at which they mine with no long-term thought about what they’re going to do with these parcels—that’s the thing that needs to be slowed so far down,” Auch said.

The irony, he pointed out, is that while farmland is being lost in pursuit of silica, the corn and soy farming happening on the same fields is also driving the demand for fossil fuels, and therefore frac sand. Nitrogen fertilizers are made from natural gas. The insecticides that coat nearly every corn seed and the herbicide sprayed to keep the weeds down are also made from oil and gas, while the tractors and trucks used to farm these crops also run on fossil fuels.

“My hope is that fossil fuels will go away, and when that happens, all of this will go away, too. But I’m not sure it’s going to happen in my lifetime,” Konczak says, her neighbors in North Utica nodding along. “I think it’s going to happen, but how long is that going to take? How bad do things have to get?”

This story is part of an ongoing Civil Eats investigation. Contact senior staff reporter Lisa Held at lisa-at-CivilEats.com or securely at lisaelaineh-at-protonmail.com. Ask her for her Signal info.

September 4, 2024

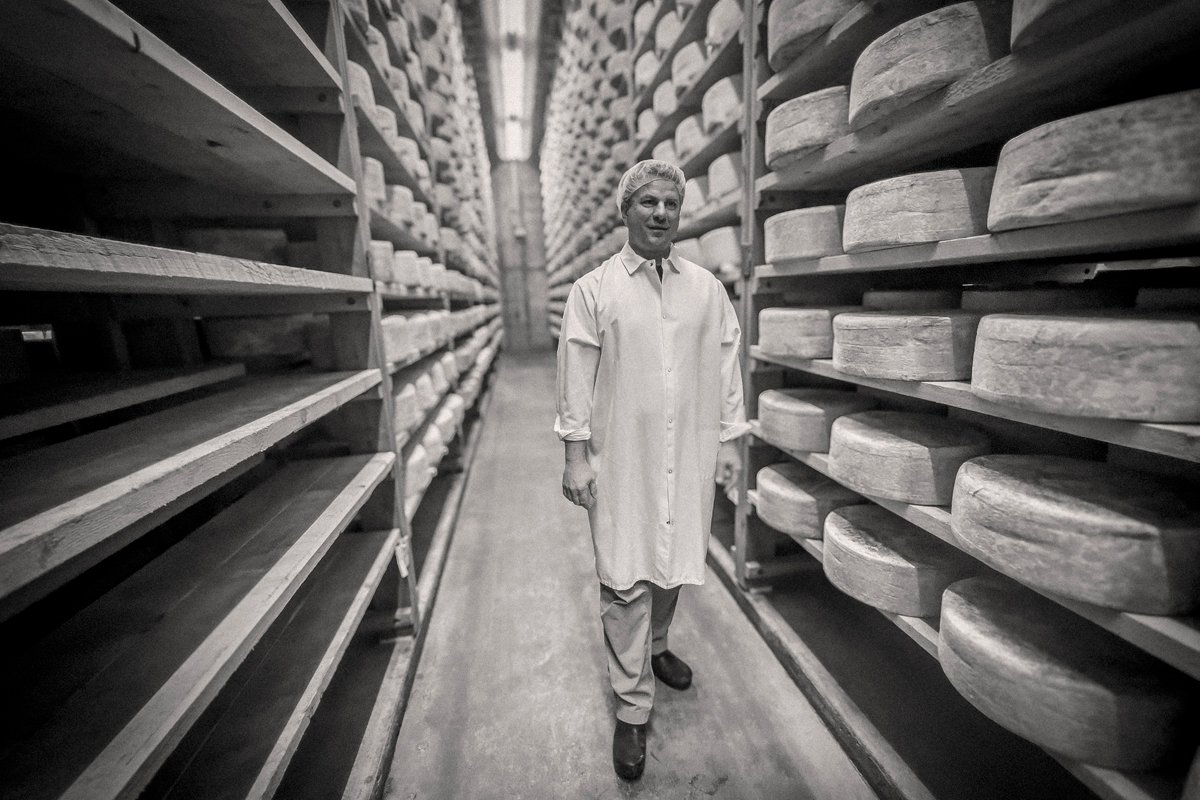

By paying top dollar for milk and sourcing within 15 miles of its creamery, Jasper Hill supports an entire community.

September 3, 2024

August 27, 2024

August 26, 2024

August 13, 2024

Like the story?

Join the conversation.