The most ubiquitous tool on America’s farms is also the most dangerous. And a nationwide program to help farmers install safety devices on their tractors is at risk of losing funding next year, unless Congress takes action.

The most ubiquitous tool on America’s farms is also the most dangerous. And a nationwide program to help farmers install safety devices on their tractors is at risk of losing funding next year, unless Congress takes action.

December 11, 2023

On a sunny afternoon in September 2021, Michael Langford was moving compost with his compact John Deere. The front bucket was half full as he drove the tractor forward on a gentle slope of his 10-acre produce and poultry farm in Greensboro, Georgia.

Suddenly, the 53-year-old felt a tire slip under him. “I felt the tractor tilting over,” Langford recalls. “I wanted to get away from it as fast as possible. Thankfully, I didn’t have my seatbelt on. It just threw me across the yard, about 40 feet.”

In the end, the tractor landed on its left side; a roll bar above the seat prevented it from turning upside down.

Initially, Langford had only scrapes and bruises on his shoulders and neck, but a few weeks later, he couldn’t raise his arms above his chest. He underwent two surgeries to address torn rotator cuffs in his shoulders.

The tractor, the most ubiquitous tool on America’s farms, is also the most dangerous. Tractor accidents can result in severe injuries and are also the leading cause of death for farmers, according to the National Institute for Occupational Safety and Health (NIOSH).

Rollovers alone account for most fatalities. Exact numbers are difficult to tally, but based on the most recent information from the U.S. Bureau of Labor Statistics, 417 people died in tractor rollovers between 2011 and 2018—an average of 52 every year. And given the fact that many farms have 10 or fewer employees and are therefore not required to report fatalities, the number is very likely higher.

A safety device called the rollover protective structure (ROPS) has been known for decades to prevent these deaths. The structure includes a roll bar above the seat, supported by two or four posts, or a crush-proof cab. When used with seatbelts, ROPS are 99 percent effective in preventing injury and death.

“Rollovers can happen anywhere. Slopes and hilly terrain are definitely high risk. Mowing ditches is pretty risky. But it can totally happen on flat ground.”

In 1985, tractor manufacturers adopted a voluntary standard to include ROPS and seatbelts on all new tractors over 20 horsepower. Older tractors can be upgraded by installing ROPS—and farmers can defray the cost, which varies from less than $200 to nearly $6,000, depending on the make and model of tractor—through a national rebate program that began in 2007.

The National ROPS Rebate Program helps farmers with approximately 70 percent of the cost of purchasing and installing the safety equipment. The Northeast Center for Occupational Health and Safety (NEC) administers the program, and states cover the cost of the actual rebates, though the amount of support states provide varies widely and waiting lists are common.

Despite the proven success of the safety measure, however, the NEC is facing a funding shortfall and may have to shut down the program in 2024—because even if states continue to supply money for rebates, if the NEC doesn’t have money to administer the program, it cannot continue to run. To keep it going, administrators need $125,000 a year.

Given the threats to the rebate program’s existence, researchers and trade groups are hoping to shift its funding—both its administrative costs and the rebates themselves—to the federal farm bill, which would offer the program more long-term stability and move thousands of farmers off years-long waiting lists to upgrade their tractors. So far, however, Congress has not introduced any legislation that would create the rebate program.

Older Tractors, Experienced Farmers

Tractor overturns have been reported since the 1920s. The vehicles have a high center of gravity that can shift when they are hauling heavy loads or lifting large items such as bales of hay, according to Dr. Brandi Janssen, director of Iowa’s Center for Agricultural Safety and Health at the University of Iowa.

“Rollovers can happen anywhere,” Janssen said. “Slopes and hilly terrain are definitely high risk. Mowing ditches is pretty risky. But it can totally happen on flat ground.” Older tractors, with their narrow “tricycle-front” wheels, are more prone to tipping over, she continued.

Farmers hang on to older tractors because they know how to repair them and they work well with their other equipment, according to Dr. Julie Sorensen, director of the NEC. “Having worked with farmers for over 20 years, “they do have an attachment to their equipment,” she said.

Missouri has the highest number of fatal tractor incidents nationwide. It was on Janssen’s family farm in the state’s Ozark Mountains where her uncle rolled his tractor—which had no ROPS—into a ravine in the 1980s. “The tractor got hung up above him and he dropped down into the ditch so he walked away from it,” said Janssen. “Those are the stories that we don’t capture in [the existing data].”

The vast majority of reported deaths happen to experienced farmers, according to the NEC.

That is evident in Washington state, where between 1998 and 2022, 24 tractor rollovers resulted in fatalities, and all the victims were men, with a median age of 54. In one instance, a 56-year-old man had worked on his father’s farm all his life.

In late July 2020, he was driving a 1971 International Harvester 1066 tractor—which did not have an ROPS or a seatbelt—with a trailer near the edge of a bumpy road before sunrise. As he turned the tractor, one of its front wheels caught in a rut and the massive machine rolled down a grassy embankment. The heavy metal arms of a 3-point hitch at the back of the tractor pinned the farmer on his back and killed him. He was found hours later by his wife and son.

Paul Karolczyk, a research investigator with Washington’s Fatality Assessment and Control Evaluation (FACE) program, published a detailed report on the incident. He found that the victim had only used the older tractor because the newer, safety-equipped tractor he owned had recently developed engine problems.

“It hit me when I was reading his obituary,” Karolczyk said. “There were a lot of comments . . . that really communicated the repercussions of this traumatic incident. We’re talking about rural communities that have smaller populations, and those impacts are felt much more widely through communities, because it’s not just one employee out of thousands. It’s also somebody who might be a pillar in that community.”

Most of the rollovers in Washington occurred on crop farms, including the state’s signature apple orchards. On those operations workers often take the roll bars down to work under the trees.

“Then they have to travel to another part of the farm, and in their mind, it takes too long to stop and put that ROPS back up,” said Todd Schoonover, director of the state’s FACE program. “But they’re going to go 30 miles an hour over some rough terrain. They’re going to navigate some tight, hairpin corners, and that’s when these rollovers often happen.”

Children at Risk

It’s not just farmers and farmworkers who are at risk. Rollover accidents can also impact children. Farms are a unique live-work space where young children often grow up riding in tractors with parents and grandparents, and older youth often help out their families and get hired by neighbors to operate tractors.

In 2011-2020, agriculture was the industry with the most deaths for working children ages 17 and younger, according to the National Children’s Center for Rural and Agricultural Health and Safety. The problem is even more pronounced because agricultural injuries and fatalities for non-working children are not recorded.

For child workers, the category that includes tractors, along with all-terrain vehicles (ATVs) and utility task vehicles (UTVs), was tied to the most deaths, according to Dr. Marsha Salzwedel, a project scientist at the center. Rollovers are more prevalent in older children driving tractors, she added. Parents will often teach children on older tractors without ROPS so they don’t damage expensive, new vehicles. But even practiced children face risks.

“We’ll hear stories about children who aren’t tall enough to reach the pedals or the steering wheel, so they have to slide forward on the seat and they don’t have the seatbelt on,” she said. “The other thing to consider is whether they have the cognitive abilities, the cognitive function, to operate that tractor. They don’t have the experience to know that you need to go crossways on a slope.”

That was the case with Ward Gerhardt in upstate New York. He learned to drive a tractor at age six on an old John Deere H that ran on kerosene. At 16, on a sunny fall afternoon, he started up a tractor for a trip down a hill. Hitched to the back was a 12-foot-high chopper wagon filled with oats from his brother’s field. Gerhardt turned up the radio over the noise of the tractor. He left his seatbelt unfastened as his foster brother sat wedged on a fender beside his seat.

“I don’t know what I was thinking, but instead of going down around the path that I should have, I broke over the crest of the hill,” Gerhardt recalled.

The six tons of grain he was towing suddenly piled forward in the wagon. The tractor’s tires lost traction, and it raced down the hill in a 25 mile-an-hour free fall. Gerhardt managed to steer straight until the tractor hit two rutted cowpaths a thousand feet down and then tore through a fence and crashed sideways.

“We got jostled around pretty good, but we got out of it without any injury,” Gerhardt said. “When it rolled, [my foster brother] was just lying there on his back and didn’t get hurt.”

That accident took place 50 years ago. An enclosed cab on the tractor kept the teenagers safe. Gerhardt, now 66, farms organic hay on his own 10-acre field in Mohawk, NY. He said the accident still affects how he drives a tractor.

“Fortunately, most of the land I’m working with is pretty flat,” he said. “Any hilly land, I’m pretty apprehensive about. I’m overly careful with how I’m driving on it and where I’m going.”

ROPS Rebates

With help from the National ROPS Rebate Program, Gerhardt is now planning to upgrade his own John Deere 3020 with a roll bar and a seatbelt. Since 2007, the program has retrofitted nearly 3,500 tractors, with rebates totaling more than $3 million. More than 2,000 farmers across the country are now waiting, because states must set aside funds for the rebates, and only New York and Minnesota have budgeted enough. A farmer in Maine has been on the waitlist for nearly 17 years, and in Iowa, the state with the highest rate of rollovers, 135 people are waiting for a rebate.

Jolean Johnson, 66, was waitlisted for five years before she upgraded the oldest of her four tractors. She uses the John Deere 2840 to rake hay and move wagons on her hilly 28-acre horse boarding farm outside State College, Pennsylvania.

Soon after she purchased the farm in 1984, Johnson witnessed her father nearly flip his tractor backwards. She bought the John Deere in 1986 and has been looking to upgrade ever since.

“It has always been an issue for me, because of how close I came to losing my father,” said Johnson.

But with her tight budget, the cost was prohibitive. When she got approved for a rebate, she paid $1,300 for the ROPS and installation. The rebate reduced her outlay to about $430.

“We’ve come so far in identifying a solution, but all of that will fold in [less than] a year if we can’t find some way to support the program.”

But other farmers may never make it through the waitlist. The NEC has relied on research grants to administer the program, including a website to apply for the rebate, a toll-free hotline manned by a former dairy farmer, recommendations for local installers, and rebate processing. But because the program is past the research phase, it no longer qualifies for the grants it has relied on in the past. Sorensen, the director of the center, estimated they need at least $125,000 per year to keep the program running at its current level nationwide.

“We’ve come so far in identifying a solution,” she said, “but all of that will fold in [less than] a year if we can’t find some way to support the program.”

She said they could charge states for administrative costs but that seems unlikely as they already struggle to provide funding for the rebates themselves. A more permanent solution would be to fold the rebates into another program: the next $1.5 trillion farm bill. (The last bill expired in September but Congress recently granted a one-year extension in funding, until September 2024.)

“The funding mechanism that’s most ideally aligned with providing rebates and funding the program would be USDA,” Sorensen said. “To provide national funding for rebates would be something like $1 million a year. If you look at the farm bill, that’s peanuts.”

Trade groups that lobby legislators, including the American Farm Bureau Federation, also support federal funding for the rebate program. And the Association of Equipment Manufacturers lists the rebate program as one of its policy priorities for the farm bill.

So far, no one has introduced legislation that would support the program. With the one-year extension, however, Congressional agriculture committees have extra time to draft the next bill, and to include the rebate program.

“[Tractor rollovers are] the most frequent cause of death in the farm community, and we have a solution that we know works,” Sorensen said. “We could prevent further death or injury in the community. And the only thing that is stopping us is a marginal investment nationally in making this happen.”

September 4, 2024

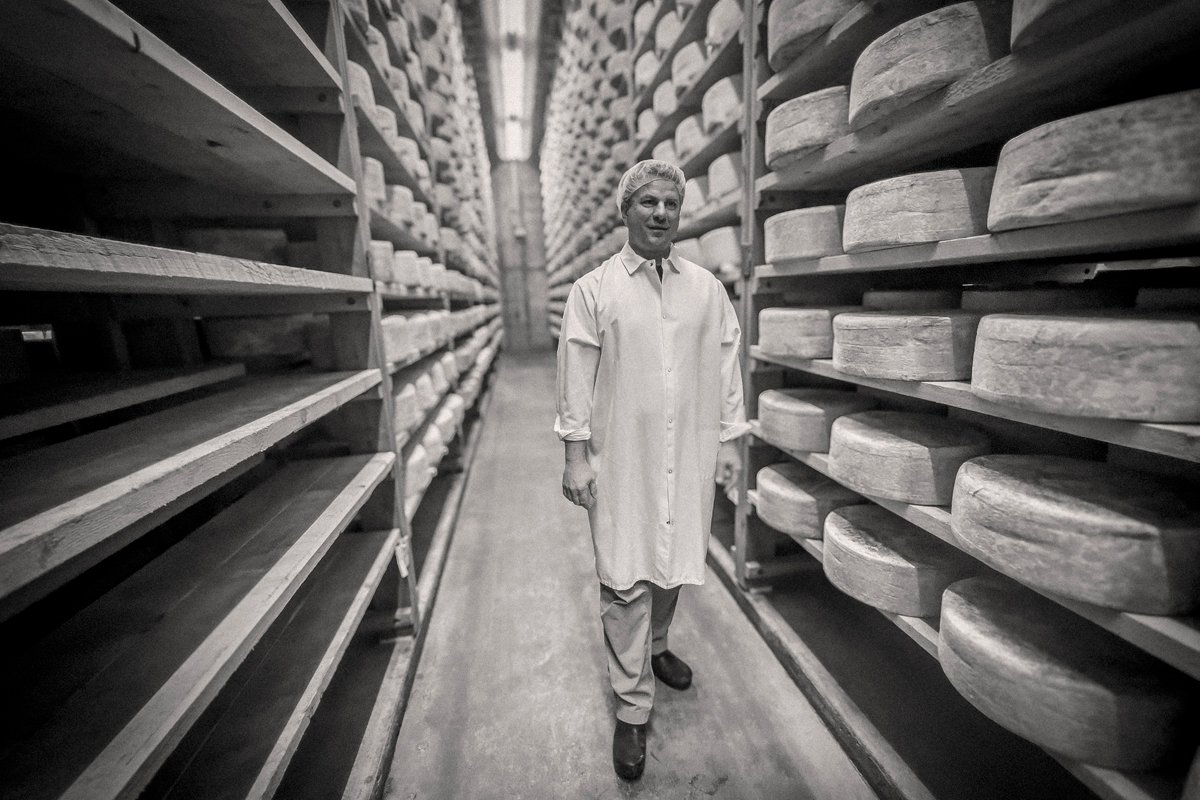

By paying top dollar for milk and sourcing within 15 miles of its creamery, Jasper Hill supports an entire community.

September 3, 2024

August 27, 2024

August 26, 2024

Like the story?

Join the conversation.