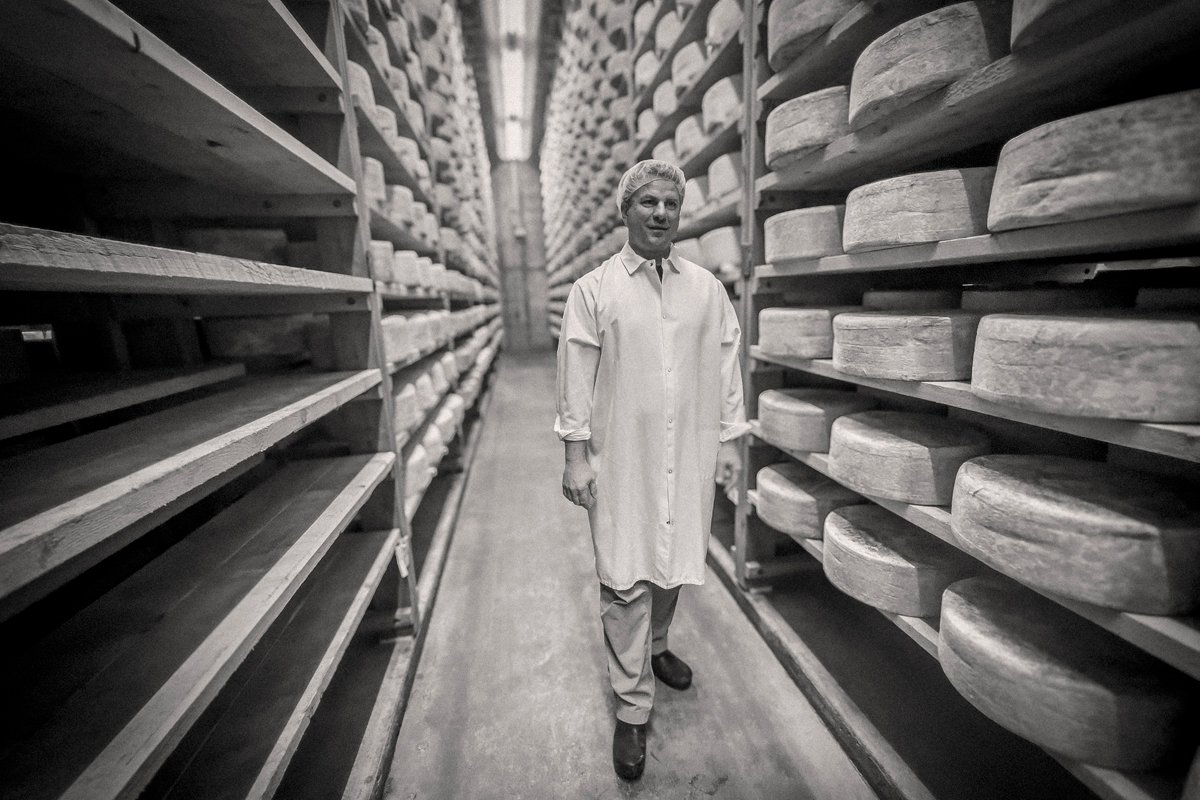

By paying top dollar for milk and sourcing within 15 miles of its creamery, Jasper Hill supports an entire community.

October 25, 2021

On a blazing August afternoon, baker-turned-miller and grain expert Don Lewis stands outside a drying tunnel at Hudson Valley Seed Company’s farm in Kerhonkson, New York. Observing the shafts of golden brown heirloom and ancient cereal grains inside the tunnel—the survivors of his two dozen test plots—he shares what led to his life’s work.

Lewis’ parents were chicken farmers outside of Middletown, New York in the 1950s, raising thousands of birds for meat and eggs. Lewis recalls his mother’s warnings. “‘Don’t be a farmer,’” she’d tell him. “‘Try to help the farmer. Buy their crop so that they can sell it. Then you do whatever with that.’”

Lewis took her dictum to heart, and for more than 20 years, he’s been on a mission to develop a robust market for regional grains in the Hudson Valley. He now runs Wild Hive Community Grain Project in Clinton Corners, New York, a milling operation that uses traditional stone grinding equipment to process small batches of organic and heritage spelt, rye, and other whole grains produced on local farms. He sells the resulting grains at area restaurants, bakeries, and specialty stores across the Hudson Valley and, since the pandemic, to retail customers through his website.

Lewis’ journey began in 1982, when he began raising bees as a commercial beekeeper, helping to pollinate orchards in the Hudson Valley. In addition to selling his honey at farmers’ markets in New York City, he used it to produce baked goods in a commercial kitchen. Then, in 2008, he opened Wild Hive Bakery and Café.

Around the same time, he was introduced to locally grown, freshly milled flour and was immediately enraptured by its range of distinctive flavors and superior nutrition compared to conventional flour. Worried his children and the ensuing generations wouldn’t have access to the fresh food he had growing up, Lewis began milling and baking for the bakery and café using locally grown flour. Seeing its potential, he closed the bakery and café in 2012 to mill full-time.

But Lewis is not simply a miller. He also has a progressive vision to broaden and diversify the food system by introducing unique grain varieties and adapting them to present-day climate conditions. Since 2016, he has partnered with the Hudson Valley Seed Company, the Hudson Valley Farm Hub, and Cornell’s Small Grains Genetic Research Program, testing near-forgotten ancient and heirloom grains. He’s looking for older genetics from all over the world that possess what he calls “very good qualities for growing in the Northeast, and for post-harvest production, milling, cooking, and eating.”

Lewis views resurrecting and adapting these older grains as a natural outgrowth of his goal to develop a network of local grain production. Without fostering biodiversity, the current system of growing grains, he asserts, “is not really good for our agricultural system nor our health.”

Reviving the Hudson Valley Grain Economy

The Hudson Valley was once considered the breadbasket of Colonial America, but as the country expanded westward, so did its amber waves of grain. The area’s grain economy collapsed as a result of deficient farming practices and the opening of the Erie Canal in 1825, which revolutionized transportation, dramatically decreasing costs. Agricultural practices, including milling, became centralized and industrialized, eventually leading to monoculture in farming.

Lewis hopes that by providing residents access to a diversity of fresh food, he can help empower the region to flourish economically, socially, and culturally and is encouraged that the model he built connecting grower, miller, baker, and distributor has influenced others across the country to develop their own. While large companies and big mills dominate the grain industry, a patchwork of efforts similar to his have sprung up, including some in Maine and South Carolina.

Educating consumers and farmers to create demand is a big—and often challenging—part of Lewis’s job. He spent years distributing local bread samples, as he believed people could only understand it by eating it. Once he selects a grain, he persuades farmers to risk growing something new, hoping they will be enthusiastic about the results. After a successful grow-out, he also convinces bakers to use his flour, which is expensive.

Lately, Lewis has seen regionally grown heritage grains gain traction with consumers, who are increasingly interested in healthy eating and the origins of their food. Business has tripled in the past five years, though this summer’s slow time was especially slow and an early-pandemic sales jump of 25 percent to retail customers has not been sustained.

Still, he believes in his mission, and despite the recent slump, this past spring he added two mills to double Wild Hive’s capacity and to improve the quality of the flour.

Experimental Work

It takes an average of four years to successfully plant, acclimate, grow out, and bring a new grain variety to market. Since 2016, when Lewis began working with Hudson Valley Seed Company to grow seed test plots, he and the company’s head farmer Steven Crist have tested approximately 30 varieties.

During the growing season, Lewis visits the plots four or five times to see how the wheat is standing, take progress notes, and consult with Crist, who’s responsible for sowing, monitoring, and harvesting it. Lewis also keeps test and grow out plots at a few nearby farms and Hudson Valley Farm Hub.

Lewis tends towards European, Eastern European, and Mediterranean varieties because the genetics are unchanged, unlike North American wheat, which has been commercially bred for mechanization and increased yield. He doesn’t want to set aside the plants’ natural qualities. “I want to be able to eat and enjoy them and their uniqueness,” he says.

Lewis says only about six varieties, including a French Rouge De Bordeaux wheat, have successfully launched. He planned to release a German einkorn variety and Estonian high-protein rye this year, but rain destroyed the crops’ quality, underscoring further obstacles to his work.

“Early-stage experimental work on new varieties and species—I’m not sure anybody else is doing that, certainly in our region,” says Stuart Farr of Hudson Valley Hops & Grains, who has grown grains for Lewis for six years. “It’s by no means a widespread activity.”

Farr and Lewis will soon embark on interplanting winter wheat and overwintering peas, an ambitious test that has the potential to enable farmers to more widely adopt growing these older wheats that are tall and frequently lodge or fall over. (When a grain lodges, or bends at the stem, the flow of nutrients to the plant is restricted, making it more susceptible to pests, disease, and declining yield.)

In interplanting, a growing method not commonly used in the grain industry, farmers plant two varieties together. Farr has used interplanting before, but not for growing grain. He was intrigued by the idea, in which the peas act as a trellis for the wheat. The peas, which can be used for animal or human consumption, fix nitrogen in the soil that the wheat then uses to grow.

“That’s pretty Kumbaya,” says Lewis. Even if the grains of a test plot lodge, he looks past that deficiency to determine if the variety can still provide value. “I evaluate the seed for what it is, the amount it produced, its health, how disease-resistant it is. If it has good scores [on flavor, the size of the cane, and the strength, even though it got knocked over], to me, there’s hope.”

Lewis also frequently trades knowledge with Professor Mark Sorells, who leads Cornell’s Small Grains Genetic Research Program, which devises innovative approaches to develop superior crop varieties. Lewis has helped select genetics for test plots and run milling tests for the Cornell program. In turn, Sorells has facilitated larger grow outs and analyzed grain for Wild Hive.

A Finely Honed Palate

A vital food system starts with seed, its most important component, says Lewis. He sources from farmers, seed banks, and a small network of seed savers around the country that entrusts their seeds and careful notes to him. They don’t have the bandwidth to further test, plant, grow, process, mill, and bring varieties to market, a seed savers’ dream, but Lewis does. Once, Lewis even brought home from a conference in Italy a teaspoon of seeds tucked into the coin pocket of dirty jeans rolled up in his suitcase.

Lewis’ unique skill set is baking, milling, and serving as a storehouse of knowledge acquired from working with breeders and growers, abilities not many other stone millers possess. Thanks to his finely honed palate, he can sample a kernel of wheat while it’s growing to determine how it may mill and taste. He can then create specific flour blends with structure, flavor, and texture to achieve the nuance desired by the bakers. For example, he might select a hard red wheat that many would pass by because they find it too bitter despite its other worthwhile qualities.

That’s key for Farr, who says Lewis’ big value is in “finding use for the grains” at a regionally significant scale that can work for farmers. “If there’s nobody other than a few home enthusiasts who are going to use it, that’s not going to do anything,” he says.

Despite the obstacles, Lewis believes trying to propagate rare varieties that have been nearly lost is a smart idea. “Coming to fruition like this reaffirms all I go through,” he says, pointing to the dried sheafs of grain at the Hudson Valley Seed farm. “I nickel and dime everything with duct tape and baling twine,” he says of his painstaking, self-funded, grassroots efforts. “It doesn’t pay me; it’s a labor of love.”

Adapting to a Changing Climate

Lewis disagrees with the view many hold that growing a monoculture is the only way to feed the world. “I look at it at the opposite,” he says. “Every region, every climate has its issues. You need to be able to adapt to that and not expect out-of-the-box genetics, where you just open that bag of seed and plant it, because a large corporation says it can grow anywhere.”

Preparing for the climate crisis is a critical piece of Lewis’ endeavors. The grains have to grow and produce yields despite unpredictable changes to temperature, precipitation, and humidity.

To assimilate a grain, farmers grow and harvest Lewis’s selected seed, often by hand. Lewis then evaluates the results, and they continue that process on a bigger plot consecutively for a few seasons. If and when the grains score high enough, they’re considered assimilated and can be brought to market. “Whether they survive and how they adapt is important,” Lewis says. “It’s a new focus on seed qualities, the ability to adapt, or to withstand all the extremes—wet, especially.”

Though the Northeast has a diverse climate, with cold winters and hot, humid summers, rain this year wrought the worst effects he’s seen on grain crops yet.

“This is an issue, and the survivors are here,” Lewis says, gesticulating excitedly towards a bunch of a rare hull-less emmer rye mix he plans to grow out this fall—and to market beginning in 2022. “They are adapting,” he continues. “[The grain] has to be able to make a left or a right turn and survive with the proper care.”

Lewis and Crist examine the grains, including a Middle Eastern Hourani Durum, and confer about future tests as they load bunches into Lewis’ van to be cleaned and threshed at the Farm Hub. “Don is the grain wisdom here,” says Crist, though they’re both fulsome in their praise of the other and their like-minded partnership to safeguard and perpetuate these varieties.

“The wisdom is that these [grains] have good, unique qualities that need to be preserved,” Crist adds, bemoaning Big Ag. “[Big aggregate business] turns bread into something different than this ancient grain that has merit that can’t be stated in a sentence. It’s a story, a history, [a] culture, [a] quality.”

Modest about fostering the region’s grain-growing renaissance, Lewis is heartened by increased participation across the country. He likens it to a bicycle that starts to move. “And other people see it and say ‘I can do that. Oh, I’m gonna do that.’ Then they do it.”

Lewis wanted to create a legacy, an improved food system for the future and for his children’s generations. “I feel as though I’ve accomplished that,” he says, “having helped to develop awareness [among] consumers, growers, and in the industry.

“The real value is in the end result,” he says. “And in being able to have a team that enthusiastically participates. That’s the future.”

September 4, 2024

By paying top dollar for milk and sourcing within 15 miles of its creamery, Jasper Hill supports an entire community.

September 3, 2024

August 27, 2024

August 26, 2024

August 20, 2024

August 13, 2024

August 12, 2024

Like the story?

Join the conversation.